Unlocking the Essence of Rigging: Geotextile Integration and its Impact

Rigging is the silent force behind various industries, from construction to maritime operations, empowering the lifting and secure movement of hefty objects through ropes, cables, and advanced equipment. Within this domain, the integration of geotextile materials has redefined efficiency and endurance, marking a pivotal shift in applications.

Where does rigging find its primary applications?

Rigging transcends industries. In construction, it facilitates the precise positioning of formidable materials like steel beams and concrete blocks. The entertainment sector relies on rigging for stage setups, securing lighting rigs, sound systems, and performers’ safety. Additionally, in maritime operations, rigging is indispensable for lifting and securing cargo on ships.

What techniques form the backbone of rigging?

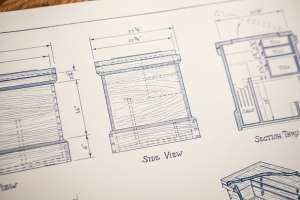

Numerous rigging techniques cater to specific tasks. From bridle rigging that evenly distributes weight using multiple ropes to block and tackle systems providing a mechanical advantage in lifting heavy loads, each technique serves a distinct purpose. Slings and hitches, adept at securing objects safely, also feature prominently in rigging practices.

How does geotextile material revolutionize rigging?

Geotextiles, engineered fabrics synonymous with construction and civil engineering, have reshaped rigging applications. Their robustness, durability, and resistance to environmental factors make them ideal for stabilizing soil on construction sites. In rigging, these materials craft resilient slings and harnesses, amplifying load-bearing capacities and ensuring the safe movement of weighty objects.

What safety considerations govern rigging operations?

Safety remains paramount in rigging endeavors. Professionals meticulously ensure equipment integrity, proper weight distribution, and adherence to prescribed limits. Regular inspections of ropes, cables, and harnesses stand as critical preventive measures. Rigorous training in techniques and load calculations forms the cornerstone of safe rigging operations.

In summary, rigging stands as a linchpin across diverse industries, driving efficiency and safety. The integration of geotextile materials heralds a new era in rigging, fortifying strength and endurance. As technology evolves, innovative materials like geotextiles continue to redefine rigging’s capabilities and safety benchmarks.