The Making of a Cabinetmaker – Part II –

My actual experience at the bench as an embryo cabinetmaker began when I was fourteen years of age. I had been at school all the winter and spring, but was with my father in the shop a great deal before and after school hours. At this time my father was working on piece work in the town of C, and in every odd moment I helped him all I could. He made a great many extension tables at so much a foot. They were 8, to and 12-foot tables, some were of black walnut but most were ash.

There was only one thing I could help him about on these tables and that was, after he had planed and scraped the tops I would sandpaper them. He had a cork block around which he folded the sandpaper, and after admonishing me to sandpaper only with the grain I would go at it. I took kindly to the work and he let me tinker a good deal for myself, and I became greatly interested in making a toy bureau. I made the frame, glued it together and get out the drawers, fitting them as well as I could. The first bureau was rather crude but I was proud of it.

I was given some practical lessons in shoving a plane. Like all beginners, I was awkward. Though I had seen my father use a plane from earliest recollection, when I attempted to use one in planing a hardwood board level, or to make a “rub” glue joint, what looked so easy as my father did it was a hard enough job when I tried it myself.

But the planing was easy as compared to learning to sharpen a plane as my father wanted me to. He had a way of holding the iron peculiar to himself. He would seize it with his right hand first, with the palm downward, placing the iron on the stone at just the angle it was ground; then he would place his left hand on the iron over the right, with the fingers and thumbs placed in such a way that in moving it backward and forward over the stone in the process of sharpening there would not be the slightest rocking to the motion.

His plane iron was never rounding, and as he seldom ground his plane iron it would last a great while. He insisted on my holding the iron just his way—every finger had to be just so. It was awkward for me at first but it became quite natural in time. Much good steel is wasted by careless ways in sharpening a plane iron and there is much unnecessary grinding in consequence.

I was proud of my father as a mechanic. He loved to do good work. He had a large tool-case which hung on the wall. It was nearly full of little drawers, all dovetailed nicely by hand. How many of the woodworkers in any of the trades can do a neat job of dovetailing? In his tool-case, which was made of rosewood and mahogany, were panels beautifully inlaid with white holly. Some of the work was put in at such angles that it appeared to stand out from the surface, and often I would run my hand over it, not believing it could be all level.

This inlaid work fascinated me, so I wanted to do some inlaid work myself. Father laid out a checker board on a piece of real white basswood. I guess he thought that would do for a starter. So I got a mallet and chisel and started in to dig out the squares. After this was done I fitted into the spaces black walnut blocks, gluing the blocks well and driving them in hard. I could hardly wait until it was dry before smoothing it off. When I did, I thought it was a wonderful piece of work; but father, while he praised me some, showed me the bad points, which were numerous and which greatly mar inlaid work. But all the time I was learning the use of tools, an indispensable thing in learning any trade.

Another tool that cabinetmakers use much on hard wood is the scraper. I took many lessons on the science of sharpening this tool also, but I confess that to this day I cannot get such a smooth-cutting edge on it as father could. The scraper he used was about the width of an ordinary hand-saw near the point, and a little longer than it was wide. He used a certain small gouge to sharpen his scraper. When it was dull he would lay it down near the edge of his bench, and holding it firmly would rub the back of that gouge over it with great rapidity. He would then turn it over and treat the other side of the scraper in the same way.

Of course you know that a steel scraper will only cut when the edge is turned back at a right angle with the side. When dull, this edge must be rubbed all down. Father did this with a gouge, as just described. Then the smooth back of the gouge was used to re-turn the edge. This he did by holding the scraper firmly with one end resting on the bench, while he drew the back of the gouge quickly, but hard pressed, along the corner of the edge he was sharpening. He did this with all four corners of the two cutting edges, then he would use it on places in the stand or table top where the grain was rough, and it was quite wonderful to me to see what shavings he would cut from the roughest places with that scraper, rendering it as smooth as glass.

We often speak of the knack of doing things. Well, he had the knack of sharpening a scraper that, with all his instruction, I have not been able to quite equal. I remember distinctly the pains that my father took with me in teaching these simple yet important things, for I was not a very apt apprentice, but I liked the work, and I am glad I learned that trade; and if I had a boy who showed any mechanical tendencies at all, I would teach him or have him taught a trade. I think every boy who has natural qualifications for it should learn a trade, and if he had the chance to become president of the United States afterwards, the trade would not hurt him any and he would have it to fall back upon when he had done with the other job.

I do not remember of meeting but one man who had learned a trade who said he was sorry for it, and he was I believe an excellent workman too. He was a machinery patternmaker, and judging from the salary he received I think he had no kick coming, but he was pessimistic. Yet I enjoyed visiting him and hearing him tell of his exploits when a young man, and after he had grown older. He told me that his father, owing to his heroic treatment of a neighbor’s valuable bulldog, gave him the choice of learning a trade or going to the reformatory, and he declared to me that he was always sorry he did not go to the reformatory instead of learning a trade.

The bulldog seemed to be the turning point in his career. It happened in this wise: When he was about sixteen years of age, according to his own testimony, his conduct bordered on wildness, and one day while on his way to hunt rabbits with a loaded, double-barreled shotgun he met a couple of neighbor’s boys, and they had with them their father’s bulldog. The dog made for the hunter, and the boys told the young fellow to point the gun at the dog and he would run away.

To use his own language, “I did point the gun at the dog with both hammers raised, and the dog came right on until he seized the muzzle of the gun in his mouth, and when he did so I pulled both triggers and the bulldog vanished in the air.” The neighbor made his father pay for the dog, and the father made him learn a trade, and he seemed to think that the end of that dog was the beginning of all his troubles.

But there was no coercion about my learning the cabinetmaker’s trade. I fell into it quite naturally, and those things that I learned to do as above described came to me in sort of homeopathic doses. That is to say, I was taught these things at odd spells and a little at a time, while I was going to school. But when the summer vacation arrived I began work in real earnest and was at it every day.

My father was very particular about his glue. He had three rules which he observed: The glue must be fresh, thin and hot. In making extension tables there is much gluing to be done. The bed of the table and the leaves were glued. Of course selection was made of pieces matching the grain as nicely as possible. Cabinet work, if good, implies good glue and a knowledge of how to use it. Glue that is as brown and crumbles like rosin should never be employed in making furniture, or for any other work that depends solely upon its strength.

My father gave me short lectures on all these fundamental things pertaining to the trade. I did not appreciate them then as I do now. However, I gave heed enough so that I was not so green about the use of glue as one apprentice I heard of who, on being asked to glue two blocks together with handscrews, did so, but a moment later was seen taking the hand-screws off, and when asked what he was doing that for replied, “Well, they are squeezing all the glue out.”

Father scolded me some, and no doubt I deserved more than I got. But as before stated, I was fourteen years of age, and rapidly approaching that period in a boy’s life when he knows, or at least thinks he knows, more than his father, mother, grandmother, grandfather, great-grandfather and the whole world besides.

Every boy has to go over “Fool’s Hill.” Some are a little longer reaching the summit than others, but from fourteen years of age on their heads grow and swell at a great rate until they are past sixteen; then it gradually diminishes until they are about twenty-five, and unless “swelled head” has become chronic, at the age of twenty-five it becomes normal and less like a pumpkin.

Once while speaking to a Southern gentleman about boys, and girls too, knowing so much more at sixteen than their parents he said to me, “Do you know how we express these peculiar conditions existing between the young people and the old ones down here? Well, we say to the young people, ‘Young people think that the old people are fools, but the old people know that the young people are.’”

I told him I would remember that, and as soon as my boy began to get lofty I would spring it on him. If he is anything like his father was, I will not have long to wait. I knew a whole lot more when I was sixteen than I do now, and it was lucky for me that I learned the trade under my father’s instruction instead of under the instruction of some men I have known since, for he had mercy when I deserved to have been half killed.

As before stated, my father was making furniture at this place by piece work. All the machine work was done for him by men employed for the purpose, and the material piled up near our benches, a dozen extension tables, or dressers, or bureaus, as the case might be, at a time. He got a dozen cheap bureaus to make, which was fun for me, as I had a chance to put the drawers together.

These were not dovetailed, but the drawer part at each end was halved with a groove about ½ inch from the lower edge to receive the bottom pieces. I used glue and finishing nails, nailing the drawer end to the front, where it was halved first, and then to the back, and lastly the other end was secured to both back and front. Then it was ready for the bottom, but before I put the bottom in I had to see that the drawer frame was square.

In order to make sure, for no one can tell what an apprentice may do to get a thing wrong, father nailed two strips just the length of the drawers at right angles with the front of my bench, and by putting the drawer frame with the front of the drawer even with the edge of the bench between the strips, it had to come square.

So in this position I slipped the thin pieces of basswood of which the bottom material was made into the grooves made in the ends and front, and by nailing it along the back edge the drawer was done, except fitting to the frames so it would slide in easily without too much play. This was a job for a more advanced cabinetmaker, but I could make the drawers, and as I always liked to pound and hammer and make noise, the job just suited me.

My first knowledge of cabinetmaking, which consisted of object lessons merely, when I was very small, was in a shop where there was no machinery. In this shop there was considerable machinery for making furniture, but this machinery cannot be compared to the machinery of the present time, and as I pore over the pages of Wood Craft and examine the machinery displayed so far in advance of thirty years ago, I wonder what the next thirty years will develop in the way of improved woodworking machinery. It now seems as if the limit of perfection had been reached.

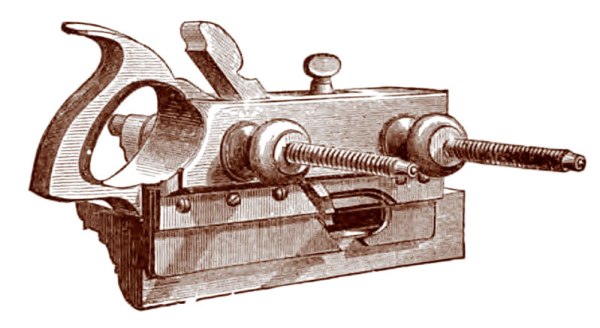

I remember an old-fashioned planer that was used in the factory for dressing lumber “out of wind” where I began to learn my trade. Instead of pushing the board to be jointed over a perfectly true and easily adjusted iron table sustaining knives that cut as smoothly as a hand-plane and as true as anything can be made, in this old machine the board was run in edgewise against knives fastened in a wheel resembling a face-plate, which knives sort of chewed and twisted the shavings off, leaving the flat side of the board fairly “out of wind” but about as rough as a circular saw would leave it.

The shaper that was used in this shop for running moldings on table tops and short legs and the like, consisted of two heads which held the knives, one running one way and the other the reverse. It was a very dangerous machine to run and two men usually operated it, I suppose so that if one got killed, or his arm or head cut off, there would be one left to report it and get the ambulance or the coroner, as the case might be.

Years afterwards I ran a carver and molder with single reversible heads, did all the work that was done upon it in a very large factory for two years and escaped with scarcely a scar. At the best these machines are extra hazardous owing to the fact that the work must be held against the knives with the hands, without the aid of feed rolls.

Another quite crude machine, which father and I used together some, was a sandpapering wheel, which consisted of a cylinder about the diameter of a barrel head and about as long as an ordinary flour barrel. The sandpaper was glued on to this cylinder and left to dry over night. It was used by holding the stand top or table leaf on to it while revolving and by moving the work from end to end it was sandpapered.

The mortising machine was also a crude affair and pounded so vigorously on heavy work as to fairly cause the building to rock upon its foundation and the chips were driven into the mortises so hard that they were with great difficulty dislodged. I know this well enough, for I had much of this dislodging to do—a job I did not like. But I was like many another apprentice, the work that I wanted to do as a rule I was not able to do and the work I was able to do I did not want to do.

There was one great advantage I had over many apprentices, I had access to all the tools I needed and it was fairly driven into my head to keep my tools sharp. How many, many boys I have known since who were trying to learn a trade with scarcely any tools and very little knowledge of how to take care of the few tools they had; trying to plane something straight and smooth with a dull plane, or trying to “beat” a mortise with a blunt chisel, or do a little carving, and sometimes the boy would not know why he could not do good work, and becoming discouraged was ready to give up as a failure when there was nothing in the world the matter except too few and too dull tools.

Even under the most favorable conditions an apprentice must be expected to spoil some work. It was so in my case, and I had the best opportunities to learn the trade. The work was by the piece and I was responsible to no one but my father. I was put right on to the bench, was not sent on any errands and therefore my time was not wasted chasing around outside, wearing away shoe leather and learning nothing, as too often is the case with boys “put out” to learn a trade.

I have known of apprentices who, by being kept doing a whole lot of odd jobs that did not pertain at all to the trade they were seeking to learn, wasted at least two out of their four years’ service. The boss would have them up at his house a good share of the time, doing anything from cleaning out a stable or currying a horse to sweeping the sidewalk, shoveling snow or drowning a troublesome old cat.

I think such treatment of an apprentice is contemptible, and a man who will do it is mean enough to steal. It is more than stealing. It is robbing a poor boy of the best opportunities of his life. I am a thousand times thankful that I had a “good show,” as we sometimes say, and I have always felt sorry indeed when I have seen boys even more apt to learn than I was compelled to do anything and everything but the steady application to those duties which involve the learning of a trade. Whether he be a young and aspiring cabinetmaker or a young woodworker of any kind, give him a chance.

Chris Weeks

Wood Craft – January, 1906

—Jeff Burks